Above image by Peter Bohler for LIAS

There’s something to seeing a Falcon motorcycle in person. While photos aplenty exist, many shot beautifully by a virtual battalion of photographers these past couple years, none can compare to actually seeing one of their bikes before you. They are a thing of striking beauty, of impeccable detail, of unchecked creativity channeled through a near militaristic craftsmanship. Years ago I did a story on Falcon, and by dumb luck I was the first non-Falconer to see The Bullet — a one-off board track racer custom built for legendary skateboarder and My Name Is Earl actor Jason Lee. I would call it an unveiling, but at the time it was just a motorcycle built for a likable TV actor, hardly more significant than any other playtoy built for a rich kid with good taste. Except it was different, it was the Bullet. And I knew right there when I first saw it, raised up on a workbench in the tiny then-workshop of Falcon, that it was a freak. Ian Barry, the man behind Falcon bikes, looked like a lunatic himself — a fried out, wild-haired sculptor who hadn’t shut his eyes in days. It turned out I was right on all counts. The weekend the bike was finished they rushed it up to Monterey for the 2008 Legend of the Motorcycle International Concours d’Elegance, where not much was supposed to happen — until infamous bike builder (and competition judge) Jesse James declared it winner at first sight. Since then the Bullet has seen fame few bikes ever have, and even fewer custom one-offs. It has graced the pages of Esquire, Playboy, Wallpaper*, Robb Report, Forbes, The New York Times and the LA Times, who’ve just posted a video of the new Kestrel (see it after the Jump). It has become a worldwide phenomenon.

Fast forward 2 years and now the second bike in Falcon’s Concept Ten series is about to be unveiled, dubbed the “Kestrel” after a falcon species that hunts in open plains. For Falcon, the Kestrel is an evolutionary leap from the Bullet that took over 2500 hours to construct — with the level of engineering, sophistication and build quality elevated to an entirely new level. I wish I could get into more specifics right now, but we’ll have to wait till after this weekend’s unveiling at the 2010 Quail Motorcycle Gathering in Carmel, California, to share with you all the dirty details. Suffice to say, Ian Barry has outgrown the customization of existing vintage motorcycles and is now designing and fabricating motorcycles from start to finish, with only a handful of parts not made from scratch.

Hit the Jump for a detailed piece-by-piece description of the Kestrel’s handbuilt development, and to see video of the new Kestrel in its entirety. After this weekend, come back for exclusive pics of the Quail Motorcycle Gathering live unveiling…

The Kestrel is the second of Falcon’s Concept Ten, a series of custom motorcycles designed around the engines of iconic pre- and post-War British motorcycles. The third, the Black Falcon, is already under construction with its 1951 Vincent Black Shadow engine drenched in California racing history. Next in line is a 1967 Velocette Thruxton, one of only seven very special “Squish Head” engines made by Veloce Ltd, which led from start to finish and won the 60th anniversary Diamond Jubilee Isle of Man Production TT race. After that will come Falcon versions of a 1936 Ariel Square Four with Over-Head Cams, a BSA, a Rudge, a Norton Cammy, and a Brough Superior. Say hello to the Kestrel below, the last Triumph Barry will work on…

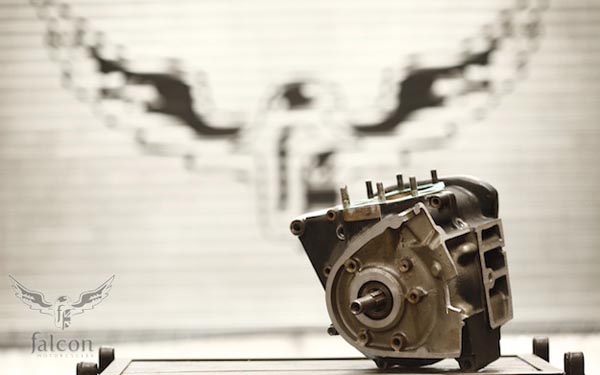

The Kestrel Falcon started life as the engine of a 1970 unit Triumph Bonneville with a damaged gearbox, that Ian Barry severed:

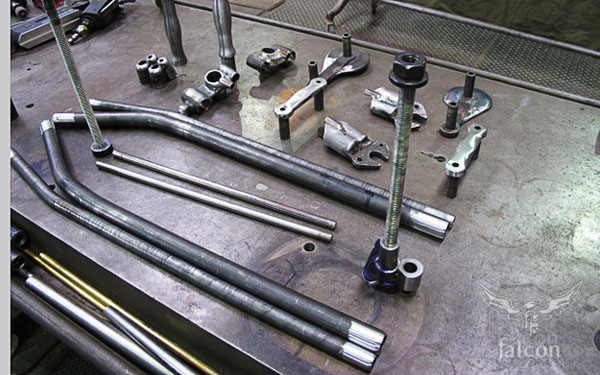

Over 2000 hours of machining, stretching, hammering, rolling and hand-carving have been artfully labored into the Kestrel, intended by Barry as his final bow to a decade of building custom Triumph-specific twins:

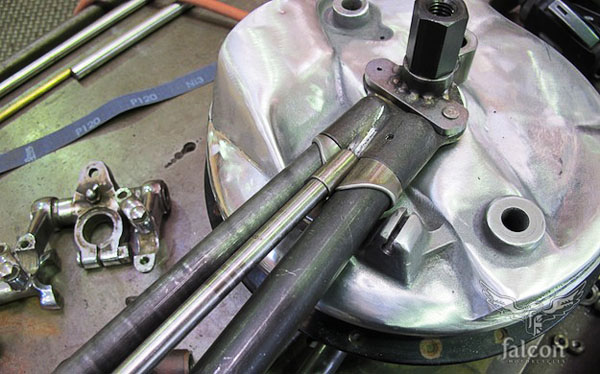

A front fork damper machined out of a block of solid aluminum, inspired from a very rare 1920 damper:

Close-up of Barry silver sauntering the frame sections. This “sweating and lugging in the frame” process is very rare in current customizing due to its high cost and time-consuming labor. Builders weld mostly to look like silver sauntering, but rarely employ this lost technique even though the silver’s strength is far superior to traditional welding:

Grinding and shaping the clutch and brake handlebar levers:

Hand-filing the various puzzle pieces of his engine cover design, to ensure seamless fit:

The Kestrel gas tank was made from scratch in-house from sheets of metal. A four-inch round section was ‘saved’ front the front of the badly rusted original Triumph tank and incorporated into the design, in order to allow the soul of the original tank to live on:

Apart from a few of the original castings, the girder forks were made from scratch on a custom made cast iron jig table:

The heavily modified and reshaped a Triumph hub:

The all-aluminum oil tank was shaped around a carved wood mold to mirror the curve of the rear wheel:

The Kestrel falcon gas tank was designed and made from scratch in-house from raw sheets of metal. A four-inch round circle was salvaged from the front of the badly rusted original Triumph tank, and incorporated into the design, in order to allow the soul of the original tank to live on:

So there you go — that’s all we can show you for now. Come back after this weekend for exclusive pics of the Quail Motorcycle Gathering unveiling, plus detailed shots of the entire Kestrel…

take me for a ride

Will they do a straight up trade for my Yamaha Virago?

Can’t wait to hear it run…

Keep it going guys! The type of creativity and commitment to quality that brought the USA on top of the manufacture world and technology, now almost gone!

[…] California to cover the unveiling of Falcon Motorcycle’s sophomore effort, the Kestrel. As I said last week, the bike is truly a thing of exceptional beauty — a motorcycle that transcends a simple vehicle […]

Very interesting build. Btw, small correction on the frame fabrication method — it’s silver “soldering,” not sauntering. This is an old-school technique used for a 100 years by bicycle builders — not because it’s stronger than welding (it’s not), but because the tubing used was very very thin, so nearly impossible to butt-weld without damage. The “lugs” used to join the tubes added strength (as well as an opportunity for craftsmen to show their flair by carving ornate patterns into them. Silver was used as the solder because it melts at a relatively low temp, so reduced any heat-induced weakening or warping of the tubes, and also required less work cold-setting (bending) the frame after it was complete to get that perfect alignment. Cool to see the technique used on a motorcycle.

Just want to say your article is as astonishing. The clarity in your post is just spectacular and i can assume you’re an expert on this subject. Well with your permission allow me to grab your RSS feed to keep updated with forthcoming post. Thanks a million and please keep up the gratifying work.

Hello…

DropshipDragon provides dropping for quality, affordable products direct from China to your customers. Perfect for eBay sellers and website owners alike!…

hello…

you have a great blog here! would you like to make some invite posts on my blog?…

Hello!…

An interesting discussion is worth comment. I think that you should write more on this topic, it might not be a taboo subject but generally people are not enough to speak on such topics. To the next. Cheers…

hello…

you have a great blog here! would you like to make some invite posts on my blog?…

Thank you…

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post….