Spent the weekend at the Quail Motorcycle Gathering in Carmel, California to cover the unveiling of Falcon Motorcycle’s sophomore effort, the Kestrel. As I said last week, the bike is truly a thing of exceptional beauty — a motorcycle that transcends a simple vehicle into the realm of true art and exquisite craftsmanship. And while there were many fine customs at the show, including superb bikes by top tier builders Shinya Kimura, Jeff Decker, Cole Foster and Jason Jesse, the Kestrel took home the award for Best Custom Motorcycle.

And while building beautiful custom bikes is not a contest, and counters the pointless effort to reduce the craft to some trophy-awarded pageant, there really was no comparison between the Kestrel and the other motorcycles gracing the Quail Country Club that sunny afternoon. It was obvious to everyone there that the Kestrel was a singular oeuvre, and has/will elevate the standard of customizations from this point forth.

Terms like “exquisite” and “craftsmanship” get tossed around a lot these days, especially by luxury or boutique brands that want to capitalize on the current trend of bespoke, tailored and custom-made identity branding — be they clothing, car kits, shoes, luggage, etc — using the minimal amount of effort necessary to make such claims. Items that consumers acquire to project to the world what one’s chosen identity is: someone of distinct taste, elevated class, singular style. But the Kestrel is true craftsman-ship, employing lost or rarely used artisan skills to an exquisite amount of effort and detail. Not for lame marketing purposes, but simply to fashion the highest caliber machine possible. And there’s a simple reason to the lack of this artistry in the modern world: it is really expensive, and really really time consuming. And in a post-industrialized world, using techniques that increase labor by 10x and cost by 20x are economically unfeasible. Only in a one-off project can this level of handcrafted detail be remotely viable.

Just look at something as simple as the foot shifter: instead of a standard metal bar, Barry designed a 3-hinged shifter, each piece hand-shaped with the subtlest of curves to create organic lines that echo original cast pieces. A transparent timing cover plate, double laser-etched with a Falcon logo, was machined to make strobe-timing of the motorcycle possible without having to remove a solid cover. The Kestrel’s split gas tank began as two sheets of raw steel that were hand-hammered around wooden molds; the tank-halves can be spread apart or tightened together by spinning the stainless steel turnbuckles, ensuring perfect tank spacing. And that is just a cursory description of 3 minor details — from axle to axle, every minor nuance was pondered and shaped (hard copper lines, hand-carved brass tank breather, hand-shaped levers, hand shaved and polished castle nuts, and so on and so on).

But all these aesthetic flourishes do not compare to the hard-core performance engineering efforts invested into the Kestrel. When Ian Barry, Falcon’s co-founder (along with Amaryllis Knight), rode the bike onto the grass field early Saturday morning all heads turned at the sound of the rumbling, deep-pitched engine. Was it possible something this ornate, hand-crafted and oh-so-pretty could actually run? Apparently so. And several hours later, when a friend of Barry’s (Vintagent’s Paul d’Orleans, no less) jumped on the bike to rip it around the lawn — and then hijacked it for a 15 minute sprint to the highway (sans helmet, btw) — it was clear the Kestrel was for real. That shit-eating grin on d’Orleans’ face upon his return was all anyone needed to see.

Hit the Jump to read more behind the building of the Kestrel. Above and below are several exclusive LIAS-only studio shots of the detailed front brake, the rare gas cap and oil tank mount (as well as the exclusive rear-view shot). Also after the Jump a second gallery of exclusive pics from this weekend’s unveiling, including pics of Ian Barry going over details with master builder Shinya Kimura and racing legend Mert Lawill, and accepting his award for Best Custom Motorcycle…

“For as gorgeous and head turning a machine as she is, once you hear that engine kickstart to life all you really want from that point on is to see the Kestrel spread her wings.”

Now that the Kestrel has been unveiled, I can finally go into a bit of the details that I was unable to disclose last week. First off, what started life as 1970’s Triumph unit engine was cut in half, separating the engine from its transmission to simulate an old pre-unit engine. As the gearbox was damaged, a BSA A-10 transmission was used. The A-10 transmission made use of a modified GS550 high performance clutch historically fitted to competition BSA Gold Star racers — a far superior clutch system to the standard Triumph or BSA, greatly improving ridability and longevity.

The amount of work involved in such a modification cannot be overstated, but what really elevates the engine to another level of engineering are its unique cylinders, designed by Barry and fully constructed in-house on their CNC machine (calling upon the expertise of their machinist Dan Kanzler). The cylinders incorporate a prototype fin design that that mates round fins on the bottom to the diamond-shaped fins on the original Triumph head. Simply put, there is no other vehicle on Earth with the same cylinders.

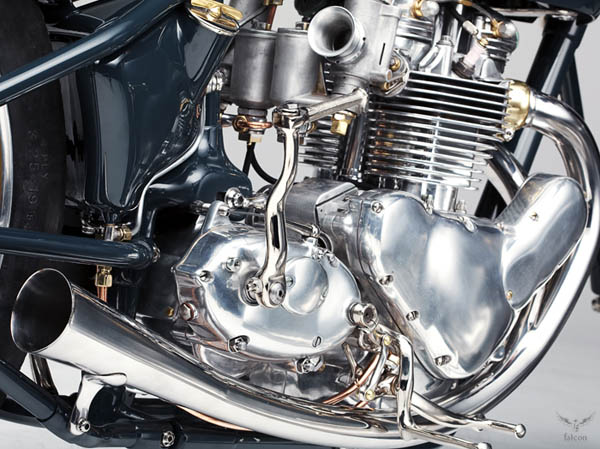

Engine detailing, including 3-hinged foot shifter and TT carbs, below

Leif Lewis, owner and engineer of Wagner-Lewis high performance Ducati clutches, was brought in to help build the engine entirely in-house. The rods and pistons are precisely fit to the crank, with big and small ends balanced. The head has honed-to-fit iron guides and racing valves, seated in a 3-angle valve job. Close attention to tolerances was adhered to throughout the entire engine — the cylinder by virtue of being CNC-machined is itself precisely made. The capacity of the engine was increased to 750cc, with an aluminum cylinder made in the Falcon shop out of a solid block of aircraft-grade 7050 alloy billet extrusion. Its thermal properties and high density, due to being compressed and formed under extreme pressure, has a strength comparable to many steels (or forged aluminum), and was the perfect choice for the Kestrel’s cylinders. It was sleeved with spun iron liners, and uses high compression pistons to cylinder fit.

The carburetors on the Kestrel are authentic, rare “handed” 1″ 3/16 amal T10TT9 racing carbs from the 1950s chosen for their unparalleled performance for the era. Positive stop adjusters were fabricated so that the idle speed could be adjusted, as the standard racing set-up didn’t have an idle adjustment. This turned the motorcycle into a street-worthy machine that has the performance potential of a true racing bike. A testament to the hours spent tuning this machine is the mere fact that it can be kick-started — given that most racing bikes outfitted with TT carbs and high compression pistons need to be push started.

Even the wheels were heavily modified, lightened by use of flanged aluminum rims and a lightened twin leading shoe brake plate. With the exception of the headstock and a small section of down tube, the entire frame was hand-built on a precision custom frame jig to ensure a perfectly straight frame and a safe geometry, and constructed using lugged fittings and silver soldered lugged joints to make it strong as hell.

It is important to note that the bike has been photographed in “Racing Trim” mode (i.e. it presently has no headlight, tail light, turn signals or license plate), as it is ready to be raced and pressed to its engineering limits at El Mirage, California, at the end of this month. Hopefully we will be there to see the motorbike test its true mettle. For as gorgeous and head turning a machine as she is, once you hear that engine kickstart to life all you really want from that point on is to see the Kestrel spread her wings. Then it will be time to see if the engineering indeed lives up to its formidable aspirations…

unfekking real!!!!!!!!!!! and wow!!!!!!!

Truly a spectacular piece of craftsmanship. Out of Ian and Amaryllis’ relentless pursuit of style, quality and perfection has come one of the most iconic motorcycles of our time. It is a pleasure to work with a small group of highly talented craftsmen dedicated to excellence…Thanks.

Seamless . Wish I could afford one of these incredible contraptions .

SLICK. I’m not a fan of this bobber boardtrack thing thats going on but this is a whole other level

STUNNING! Wonderful example of passion, talent along with first class vision of delivering nothing less than Excellent!

El Mirage baby! See ya there!

[…] brought you the unveiling of Falcon’s sophomore effort, the Kestrel, last month. While we got to see it run, the only thing the world saw was its sheer […]

[…] of the metal began to grow on me — and then when I saw one in the flesh this past May at the Quail Motorcycle Gathering, it all became clear to me. His latest bike, using a Ducati-frame customized for Devon Motorworks, […]

[…] not always the World’s Most Powerful and Expensive or World’s Most Exclusive or World’s Most Beautiful bikes that tickle our fancy, sometimes it’s the total opposite — especially if the heart […]

I just came across funny joke: Q: what makes the tower of Pisa lean? A: it never eats.

I love Bottle Cap Jewelry. I get all my bottle caps from BottleCapCo.com really cheap. Does anyone know where I can find ideas for colors and more designs?